Our

EXPERTISE

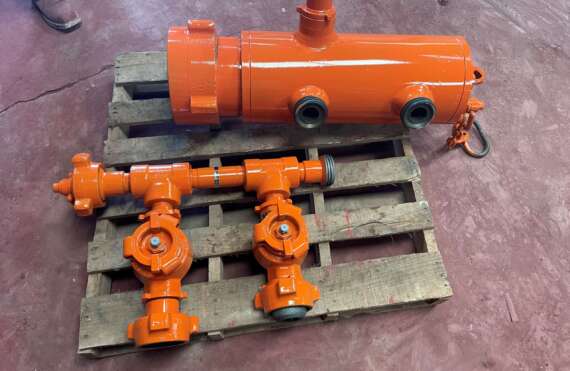

K-RAY Energy Services Flow Iron Inspection & Recertification’s team provides Flow line and Valve maintenance, Repair, Ultrasonic Thickness (UT), Magnetic Particle (MT) and Hydrostatic Testing (HT) at any location required by the client to promptly return iron investment to service.

K-RAY will spend as much time on client site as needed. Every item of flow iron equipment will be properly assessed, rebuilt, and recertified for service.

Level 1 Inspection – Visual Inspection, Ultrasonic Wall Thickness Measurement, Take Wings Off, Clean Wing End & Thread End, Banding.

Level 2 Inspection – Visual Inspection, Ultrasonic Wall Thickness Measurement, Disassembly & Reassembly, Take Wings Off, Sandblast, Band, Pressure Test & Paint.

Level 3 Inspection – Visual Inspection, Ultrasonic Wall Thickness Measurement, Take Wings Off, Sandblast, Disassemble Completely, Magnetic Particle Testing, Band, Re-assemble, Pressure Test & Paint.

Called To Serve

Service members explain what service means to them as well as their proudest moments.

BEST VALUE AND QUALITY WORK

Get an inside look at the lives of those who serve

K-RAY ENERGY SERVICES is an iron recertification company for all aspects of the oil and gas industry. Our continuing effort is committed to providing the highest quality services and products. K-RAY provides repair and recertification of high pressure flow line, valves and components. Our facility provides nondestructive testing services, hydrostatic testing services, inspection services, and rebuilding services for your equipment.